Hollow Glass Microspheres Hollow Glass Bubbles Hollow GlassBeads 0.32g/Cc

| True Density: | 0.32±0.02g/cc | Particle Size D50: | 35-45um |

| PH Value: | 7~9 | Flotation: | ≥99% |

| High Light: |

0.32g/Cc hollow glass microspheres, 0.32g/Cc hollow glass bubbles, 35um hollow glass microspheres |

||

Hollow Glass Microspheres

HGM-32P

Introduction:

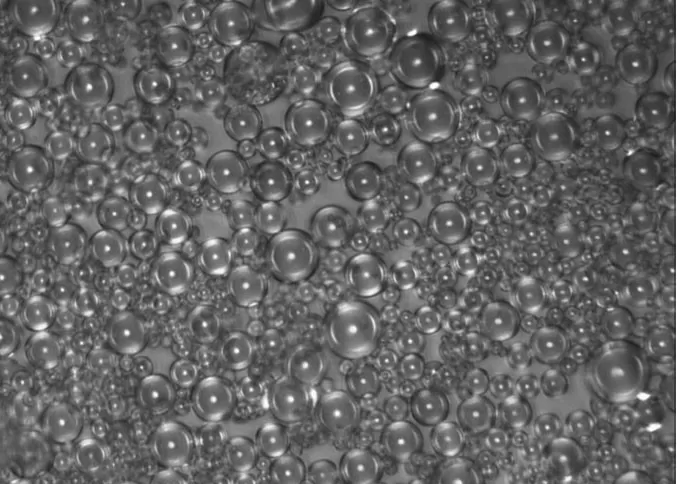

SINOENERGY GROUP by the use of modern scientific quality management system, implementation of advanced processing technology, the precise detection technology R & D and production of hollow glass microspheres. It is small ball-shaped hollow material with gas inside, which is a stable hollow particle with special performances and has advantages of low weight, large volume, low thermal conductivity and great dispersity, flowability & stability. Furthermore, it has excellent performance such as insulation, self-lubrication, sound and heat insulation, nonabsorbent, corrosion resistance, radiation protection and non-toxic. Due to special hollow structure, physical & mechanical performance and stable chemical property, it will be wildly used as non-metal additive that are non-toxic, colorless and tasteless, becoming the main trend of new composite material for 21st century.

Main Chemical Data:

| Ingredient | Concentration | CAS NO. | EC NO. |

| Silica | 70±5% | 14464-46-1 | 238-455-4 |

| Diboron trioxide | 6±2% | 1303-86-2 | 215-125-8 |

| Sodium oxide | 8±2% | 12401-86-4 | 235-641-7 |

| Calcium oxide | 8±2% | 1305-78-8 | 215-138-9 |

Main Physical Data:

| Item | unit | Standard Request | |

| Appearance | -- | White powder | |

| True density | g/cm3 | 0.30-0.34 | |

| Stack strength | MPa | -- | 24 |

| PSI | -- | 3500 | |

| Particle size D50 | um | 35-45 | |

| PH value | -- | 7~9 | |

| Rate of flotage | % | ≥99 | |

| Dielectric coefficient | - | 1.30-2.00 | |

| Thermal conductivity | W/m.k(20℃) | 0.04-0.06 | |

| Carton package | kg | 40 | |

| Ton bag package | kg | 150 | |

Storage and Handing:

Storage: Store in a cool, ventilated warehouse. Keep away from fire and heat. Equipped with the appropriate variety and quantity of firefighting equipment and leakage emergency treatment equipment.

Handing: Provide adequate ventilation. The operator must experience specialized training, strict adherence to rules. Proposed operators wear masks,wear overalls,gloves. Away from fire,heat source,water source,smoking is prohibited in the workplace Avoid creating dust. Use explosion-proof ventilation systems and equipment. Equipped with the appropriate variety and quantity of firefighting equipment and leakage emergency treatment equipment.

Parameters Table:Hollow Glass Microspheres

HGM-32P

|

ITEM |

HGM-15P |

HGM-20P |

HGM-25P |

HGM-32P |

HGM-38P |

HGM-46P |

HGM-60P |

|

|

True density (g/cc) |

0.15±0.02 |

0.20±0.02 |

0.25±0.02 |

0.32±0.02 |

0.38±0.02 |

0.46±0.02 |

0.60±0.03 |

|

|

Crush strength |

MPa |

3.5 |

7 |

10 |

24 |

38 |

55 |

82 |

|

PSI |

500 |

1000 |

1500 |

3500 |

5500 |

8000 |

12000 |

|

|

Particle size D50 (μm) |

50-60 |

45-55 |

40-50 |

35-45 |

35-45 |

35-45 |

25-35 |

|

|

PH value |

7~9 |

7~9 |

7~9 |

7~9 |

7~9 |

7~9 |

7~9 |

|

|

Flotation (%) |

≥99 |

≥99 |

≥99 |

≥99 |

≥99 |

≥99 |

≥99 |

|

|

Softening temperature (℃) |

≥600 |

≥600 |

≥600 |

≥600 |

≥600 |

≥600 |

≥600 |

|

|

Carton Package (Kg) |

20 |

25 |

25 |

40 |

50 |

50 |

50 |

|

|

Ton bag package (Kg) |

100 |

100 |

100 |

200 |

200 |

200 |

200 |

|

Application:

Application:

●Oilfield exploitation: Glass microspheres are added to various drilling fluids as density reducing agents,which can reduce the density of drilling fluids,reduce torque and friction,and enhance compression performance without affecting the performance of drilling and downhole equipment.

●Deep sea Materials: Glass microspheres are added to liquid thermosetting resin to make composite foam materials. Its low density, high strength and good thermal insulation properties have been used in marine cable floats and submarines, diving suits and rescue tools.

●Electronic: The ultra-low dielectric constant, light weight, heat insulation and insulation of glass microspheres play an indispensable role for materials such as electronic sealants, electronic substrates and heat sinks.

●Transportation: Glass microspheres are used in SMC and BMC to meet the light weight requirements of automotive, high-speed rail and marine transportation components.

●Aerospace: The low-density ablation material prepared by glass microspheres is an important thermal protection material in manned space technology. This material can also be applied to the heat protection of other aircraft with high enthalpy, low heat flux density and long-term use.

●Chemical industry: Glass microspheres improve the shortcomings of low explosive performance, uncontrolled explosive density and short storage period. They can also enhance the fluidity of coatings and reduce the emission of toxic gases.

●Building materials: Glass microspheres reduce the weight of artificial marble and furniture products, improve crack resistance, smooth appearance and reduce costs.